High delivery rate, sample delivery rate of 99.59%, 12 hour express delivery, nationwide free shipping, small batch delivery takes 1-2 days.

Choose high-quality raw materials, strictly control the manufacturing process and implement standardized quality management to create high-quality products.

Provide professional technical support with fast response and real-time feedback, and offer professional consulting advice based on customer needs.

单层柔性电路是最基本的,由层压到薄铜片上的柔性聚酰亚胺薄膜组成。然后对铜层进行化学蚀刻,以产生满足您特定设计要求的电路图案。然后添加聚酰亚胺覆盖层,以对电路进行绝缘和环境保护。

双面导通柔性电路 是一种单面柔性电路,其制造方式使得导电材料可以从电路的两侧接触。柔性电路是这项技术的领跑者,它利用专门的激光和加工技术剥开基材的聚酰亚胺层,从而实现对单个铜层的双重接触。

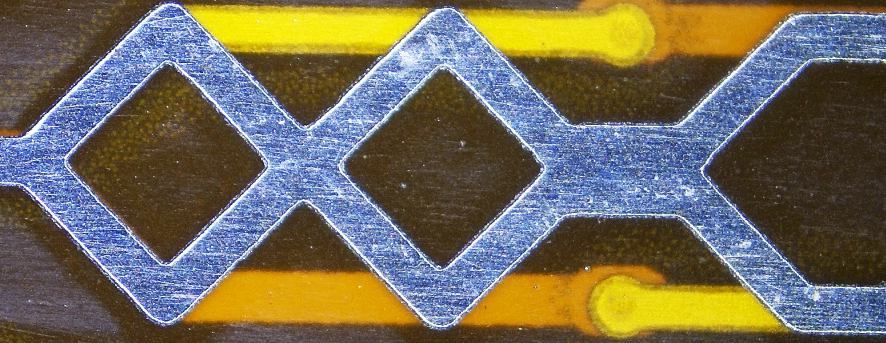

双面柔性电路是一种具有两个导电层的电路,电路内聚酰亚胺基层的每一侧各有一个导电层。可以根据您的需求在基板薄膜的两侧创建走线图案,并可以在需要的地方使用镀铜通孔进行连接。镀铜通孔在两层之间建立电气连接。

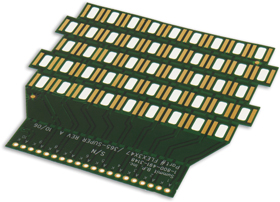

多层柔性PCB电路

将 多个单面或双面电路与复杂的互连、屏蔽和/或表面贴装技术结合在一起,形成多层设计。在整个生产过程中,多层可能会或可能不会连续层压在一起。如果您的设计需要最大的灵活性,连续层压可能不合适。当面临以下设计挑战时,多层电路是一种有效的解决方案:不可避免的交叉、特定的阻抗要求、消除串扰、额外的屏蔽和高元件密度。

在利用多层柔性电路帮助您设计解决方案时,柔性电路可以自豪地说“我们走别人走不到的地方”。

软硬结合板

已在军事和航空航天工业中使用了 40 多年。在刚挠结合电路板中,柔性和刚性材料层用于在单个封装中创建刚性和柔性区域。

刚挠结合电路将刚性板和柔性电路的优点集成到一个电路中。

刚性外层使用镀铜通孔连接到内部柔性层。刚性柔性电路提供更高的元件密度和更好的质量控制。在需要额外支持 SMT 元件的地方采用刚性设计,在需要弯曲和弯曲以适应狭小空间的地方采用柔性设计。

The single-layer flexible circuit is the most basic, consisting of a flexible polyimide film laminated onto a thin copper sheet. The copper layer is then chemically etched to produce a circuit pattern that meets your specific design requirements. A polyimide coating is then added to insulate the circuit and protect the environment.

A double-sided flexible circuit is a single-sided flexible circuit manufactured in such a way that conductive materials can be contacted from both sides of the circuit. The flexible circuit is the frontrunner in this technology, which uses specialized laser and processing techniques to peel away the polyimide layer of the substrate, thereby achieving double contact with a single copper layer.

A two-sided flexible circuit is a circuit with two conductive layers, one conductive layer on each side of the polyimide base layer in the circuit. A trace pattern can be created on both sides of the substrate film according to your needs and can be connected using copper-plated through holes where needed. Copper plated through holes create an electrical connection between the two layers.

Multilayer flexible PCB circuit

Multiple single-sided or double-sided circuits are combined with complex interconnect, shielding, and/or surface mount technologies to form multi-layer designs. Multiple layers may or may not be continuously laminated together throughout the production process. If your design requires maximum flexibility, continuous laminating may not be appropriate. Multilayer circuits are an effective solution when faced with the following design challenges: inevitable crossover, specific impedance requirements, crosstalk elimination, additional shielding, and high component density.

When leveraging multi-layer flexible circuits to help you design solutions, flexible circuits can proudly say "we go where no one else can."

Soft and hard board

It has been used in the military and aerospace industries for more than 40 years. In rigidly bonded boards, layers of flexible and rigid materials are used to create rigid and flexible areas in a single package.

Stiff-flex bonding circuits integrate the advantages of rigid plates and flexible circuits into one circuit.

The rigid outer layer is connected to the inner flexible layer using copper-plated through holes. Rigid flexible circuits provide higher component density and better quality control. A rigid design is used where additional support for SMT components is required, and a flexible design is used where bending and bending are required to fit into tight Spaces.

Monolayer flexibility

· Reduce wiring errors

· Eliminate mechanical connectors

· Unparalleled design flexibility

· Higher circuit density

· More stable operating temperature range

· Stronger signal quality

· Improved reliability and impedance control

· Reduce size and weight

Reduce assembly errors - The precise design and automated production of flexible circuits eliminates human errors that occur when wiring harnesses are manufactured by hand. Except for errors caused by production, the circuit is routed only to the point required for an accurate design scheme.

Reduced assembly time and cost - Flexible circuits require less labor during assembly and reduce production errors. Flexible circuits have the inherent ability to integrate form, fit and function. Flexible circuits eliminate the high cost of wiring, winding, and welding wires. A complete interconnect system is installed or replaced, rather than a separate hard PC board. As a result, wiring errors are eliminated, reducing manufacturing costs. Whether it is small batch production of complex circuits or large batch production of simple circuits, assembly time and cost will be reduced.

Design freedom - Unlike rigid plates, flexible circuits are not subject to two-dimensional constraints. Because flexible circuits are as flexible as wires or ribbon cables, the design options for flexible circuits are endless. At Flexible Circuits, we pride ourselves on tackling the most complex design challenges. Flexible circuits can be designed to meet highly complex and unimaginable configurations while being able to operate in the harshest environments. Flexible circuit design may involve any of the following:

· Highly complex configuration

· Withstand harsh operating environments

· Single and double combination

· Complex interconnections

· Shielding

· Rigid/flexible functions

· Surface mount equipment

The conversion of wiring harnesses to flexible wiring harnesses reduces wiring errors caused by manual connections and reduces assembly time

Flexibility during installation - Flexible circuits allow for the use of a third dimension as they can interconnect two or more planes during execution. As a result, they solve space and weight problems that rigid circuit boards cannot solve. Flexible circuits can be operated multiple times during installation and execution without electronic failure.

High density applications - Flexible circuits allow extremely narrow lines to meet the needs of high density devices. A denser number of devices and lighter conductors can be designed into one product, freeing up space for other product functions.

Improved airflow - Due to its streamlined design, the flexible circuit allows cooling air to flow through electronic applications.

Improved heat dissipation - Flexible circuits allow for shorter thermal paths due to their larger surface area to volume ratio and compact design. In addition, the thin design of the flexible circuit allows heat dissipation from both sides of the circuit.

Improve system reliability - In the past, most circuit failures occurred at the interconnect point. The design of flexible circuits can reduce interconnections and thus improve circuit reliability.

Point-to-point wire replacement - Depending on the number of point-to-point connections in the Circuit design, at Flexible Circuit we guarantee that we can design and build a flexible circuit that can eliminate many, if not all, interconnections. At Flexible Circuit, "We go where no one else can".

Reliability and durability - In designs with moving parts, flexible circuits can move and bend up to 500 million times without failure. The excellent thermal stability of polyimide also enables the circuit to withstand extremely high temperature applications. The thermal stability of polyimide provides a better basis for surface mounting than hard boards. Because the flexible base film exerts less stress on the welded joint, thermal mismatch is unlikely to occur.

Repeatable wiring - Our circuits are made with exact copies of original drawings for excellent manufacturing consistency. Etched circuits replace welded and hand-wired connections for rigid plates, completely eliminating wiring errors.

Simplified circuit geometry - Flexible circuit technology places surface-mount electronics directly on the circuit, simplifying the overall design. Complex patterns that are almost impossible to achieve using rigid circuit boards can be easily achieved in flexible circuits.

Package size and weight reduction - Multiple systems in rigid plates increase weight and utilize more space. The flexible circuit contains the thinnest dielectric substrate. The thinness allows for a more streamlined design without the need for heavy rigid plates. Elasticity and flexibility reduce package size. In addition to reducing package size, reducing package weight is another benefit. With the growing demands of the electronics industry, weight reduction keeps flexible circuits extremely competitive.

In short, if you have flexible circuit design or flexible printed circuit board needs, we can help.

304 stainless steel

Conductor - Copper is the most widely used conductor and comes in a variety of thicknesses to meet each customer's requirements. Conductor options include:

· Rolled Copper (RA)

· Electrolytic copper (ED)

· Aluminum

· Carbon

· Silver paste

· Stainless Steel ®

· Constantan

Double sided flexographic laminated adhesive

Adhesives - The choice of adhesives depends on customer requirements and conductor thickness. Common adhesives include:

· Epoxy resin

· Acrylic fiber

· Pressure Sensitive Adhesive (PSA)

· No adhesive (substrate)

Dual layer flexible circuit board with flexible solder shield

Insulators - Flexible substrates (substrates) and cladding materials are available in a variety of thicknesses and are supplied by several manufacturers. Common insulators include:

· Polyimide

· Polyester, polyethylene naphthalate (PEN) and polyethylene terephthalate (PET)

· Solder resistance layer

· Flexible solder resistance layer

· Imageable Covering Film (PIC)

· Screen printing dielectric

3 layers flexible.5 oz copper selective lead bonding Ni/Au assembly and radiator bonding

Surface treatment - The final surface treatment depends on each customer's assembly requirements and the application of the finished product. Common surface treatments include:

· Solder (tin, lead or RoHS compliant)

· Tin

· Nickel/gold sinking

· Hard nickel/gold

· Lead key alloy

Organic: entek or organic solderability Protectant (OSP)

· Silver

· Carbon

In short, if you have flexible circuit design or flexible printed circuit board needs, we can help.

Flexible assembly with LED and aluminum radiator

Radiators - Radiators can be laminated onto flexible circuits to dissipate heat from sensitive components such as leds.

Two-layer flexible module

Component Assembly - We offer through-hole and surface mount capabilities, as well as circuit testing, conformal coating and electrostatic protection packaging.

Double-layer flexible cable with controllable impedance

Controlled impedance - As signal switching speeds increase, engineers need to understand and control the impedance of the wires. Due to the short signal conversion time and high clock frequency of modern digital circuits, the wiring needs to be treated as a transmission line rather than a simple interconnection. With today's increased speed requirements, controlled impedance wiring is designed to minimize electrical reflection and ensure error-free conversion between tracks and interconnects. When perfectly optimized, the controlled impedance can control the physical size and material of the cable. Controlled impedance signal transmission requires uniform thickness and electrical properties of flexible circuit materials. At Flexible Circuit Technologies, we have extensive experience in designing and manufacturing flexible circuits with controlled impedance.

Single layer flexible crimp patch UHB adhesive antenna

Crimp pin - The crimp pin mechanically joins the circuit to achieve a welded connection.

Double layer flexible plate with pattern overlay switch

Graphic overlay - The graphic overlay can be placed on a flexible circuit, rigid plate or film switch. The overlay provides the underlying circuitry for the user interface and is usually used in conjunction with leds, LCD displays, or dome switches mounted on these circuits. The covering is made of polycarbonate, polyester or acrylic material.

Single side 0.5 oz copper laser cut with slot

Laser cutting slots and holes - In the past, people used X-acto knives or blades to cut complex areas of flexible circuits, with success depending on the skill of the operator. FCT greatly improves this process by using a top-of-the-line laser beam with extremely precise depth control to precisely cut the underlying substrate of the flexible circuit. Precise laser beams can cut circuit openings with extreme precision.

Double layer flexible circuit board with cladding molding and wire connection.

Encapsulation molding - Encapsulation molding is the process of embedding an FCT into an electronic component, rather than simply placing the electronic component on a circuit. As electronic devices and the required interconnections become more compact, embedding electronic circuits into cable assemblies is a cost-effective alternative to on-board electronic components. These embedded devices, often referred to as smart cables or dongles, can solve many packaging challenges.

Panel component assembly

Pressure sensitive adhesive (PSA) - PSA with release film is used in applications where a part of the circuit needs to be secured to a specific location within the end product. During assembly, the detached film is stripped, exposing the adhesive that allows the assembler to press the circuit into place and hold it there.

Single layer carved flexible plate

Carved flexible circuits - Carved flexible circuits are special in that the copper conductors vary in depth and thickness at different locations. The copper in the most flexible part of the circuit is thinner and the copper at the interconnect point is thicker. Sculpted flexible circuits allow bare metal connections (such as plug-ins) and remain strong while solder joints are formed. Carved fingers provide a more reliable alternative to mechanically fixed crimping pins.

Double layer flexibility with rigid component assembly area

Stiffener - Stiffener is suitable for flexible circuits that require additional support, such as component assembly areas or bare lines for connection. Common reinforcing tendons are FR4 and polyimide.

Flexible circuit with harness

Wire assembly - In some applications, a combination of flexible or rigid circuits with conventional wires may be a more economical design while still meeting customer component needs. At Flexible Circuit Technologies, we have the ability to design, procure, manufacture and assemble entire components, including circuits, wires and components. This capability and commitment sets us apart from other flexible circuit suppliers. That's why our motto is "We go where others won't".

Flexible heater

Flexible heaters - Flexible heaters are thin, flexible heating elements that are shaped to meet your unique heating equipment needs.

The flexible circuit is connected to the rigid plate by hot pressing welding

Hot pressure welding - Hot pressure welding is a method of eliminating the set of connectors between hard plates and flexible circuits. This connection provides an efficient, durable, and less expensive alternative to standard connector sets.

Laser cutting single-sided circuit to achieve dual access

In short, if you have flexible circuit design or flexible printed circuit board needs, we can help.