High delivery rate, sample delivery rate of 99.59%, 12 hour express delivery, nationwide free shipping, small batch delivery takes 1-2 days.

Choose high-quality raw materials, strictly control the manufacturing process and implement standardized quality management to create high-quality products.

Provide professional technical support with fast response and real-time feedback, and offer professional consulting advice based on customer needs.

Product category:

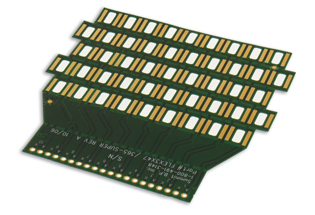

Type number: 01Y04C00269A

Number of layers: 2

Plate thickness: 0.15mm

Material: double-sided non-adhesive electrolytic material

Copper thickness: 1/2 OZ

Special point: Extra long 2.5M

Surface treatment: Gold 2 micro inches

Minimum line width/line distance: 0.07mm/0.06mm

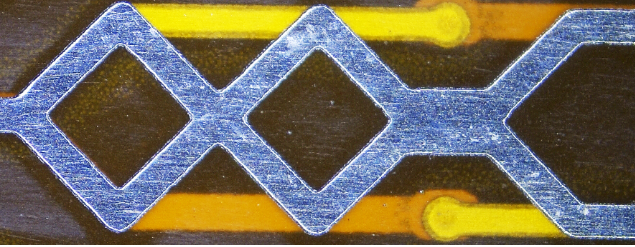

The single-layer flexible circuit is the most basic, consisting of a flexible polyimide film laminated onto a thin copper sheet. The copper layer is then chemically etched to produce a circuit pattern that meets your specific design requirements. A polyimide coating is then added to insulate the circuit and protect the environment.

A double-sided flexible circuit is a single-sided flexible circuit manufactured in such a way that conductive materials can be contacted from both sides of the circuit. The flexible circuit is the frontrunner in this technology, which uses specialized laser and processing techniques to peel away the polyimide layer of the substrate, thereby achieving double contact with a single copper layer.

A two-sided flexible circuit is a circuit with two conductive layers, one conductive layer on each side of the polyimide base layer in the circuit. A trace pattern can be created on both sides of the substrate film according to your needs and can be connected using copper-plated through holes where needed. Copper plated through holes create an electrical connection between the two layers.

Multilayer flexible PCB circuit

Multiple single-sided or double-sided circuits are combined with complex interconnect, shielding, and/or surface mount technologies to form multi-layer designs. Multiple layers may or may not be continuously laminated together throughout the production process. If your design requires maximum flexibility, continuous laminating may not be appropriate. Multilayer circuits are an effective solution when faced with the following design challenges: inevitable crossover, specific impedance requirements, crosstalk elimination, additional shielding, and high component density.

When leveraging multi-layer flexible circuits to help you design solutions, flexible circuits can proudly say "we go where no one else can."

Soft and hard board

It has been used in the military and aerospace industries for more than 40 years. In rigidly bonded boards, layers of flexible and rigid materials are used to create rigid and flexible areas in a single package.

Stiff-flex bonding circuits integrate the advantages of rigid plates and flexible circuits into one circuit.

The rigid outer layer is connected to the inner flexible layer using copper-plated through holes. Rigid flexible circuits provide higher component density and better quality control. A rigid design is used where additional support for SMT components is required, and a flexible design is used where bending and bending are required to fit into tight Spaces.

Monolayer flexibility

· Reduce wiring errors

· Eliminate mechanical connectors

· Unparalleled design flexibility

· Higher circuit density

· More stable operating temperature range

· Stronger signal quality

· Improved reliability and impedance control

· Reduce size and weight

Reduce assembly errors - The precise design and automated production of flexible circuits eliminates human errors that occur when wiring harnesses are manufactured by hand. Except for errors caused by production, the circuit is routed only to the point required for an accurate design scheme.

Reduced assembly time and cost - Flexible circuits require less labor during assembly and reduce production errors. Flexible circuits have the inherent ability to integrate form, fit and function. Flexible circuits eliminate the high cost of wiring, winding, and welding wires. A complete interconnect system is installed or replaced, rather than a separate hard PC board. As a result, wiring errors are eliminated, reducing manufacturing costs. Whether it is small batch production of complex circuits or large batch production of simple circuits, assembly time and cost will be reduced.

Design freedom - Unlike rigid plates, flexible circuits are not subject to two-dimensional constraints. Because flexible circuits are as flexible as wires or ribbon cables, the design options for flexible circuits are endless. At Flexible Circuits, we pride ourselves on tackling the most complex design challenges. Flexible circuits can be designed to meet highly complex and unimaginable configurations while being able to operate in the harshest environments. Flexible circuit design may involve any of the following:

· Highly complex configuration

· Withstand harsh operating environments

· Single and double combination

· Complex interconnections

· Shielding

· Rigid/flexible functions

· Surface mount equipment

The conversion of wiring harnesses to flexible wiring harnesses reduces wiring errors caused by manual connections and reduces assembly time

Flexibility during installation - Flexible circuits allow for the use of a third dimension as they can interconnect two or more planes during execution. As a result, they solve space and weight problems that rigid circuit boards cannot solve. Flexible circuits can be operated multiple times during installation and execution without electronic failure.

High density applications - Flexible circuits allow extremely narrow lines to meet the needs of high density devices. A denser number of devices and lighter conductors can be designed into one product, freeing up space for other product functions.

Improved airflow - Due to its streamlined design, the flexible circuit allows cooling air to flow through electronic applications.

Improved heat dissipation - Flexible circuits allow for shorter thermal paths due to their larger surface area to volume ratio and compact design. In addition, the thin design of the flexible circuit allows heat dissipation from both sides of the circuit.

Improve system reliability - In the past, most circuit failures occurred at the interconnect point. The design of flexible circuits can reduce interconnections and thus improve circuit reliability.

Point-to-point wire replacement - Depending on the number of point-to-point connections in the Circuit design, at Flexible Circuit we guarantee that we can design and build a flexible circuit that can eliminate many, if not all, interconnections. At Flexible Circuit, "We go where no one else can".

Reliability and durability - In designs with moving parts, flexible circuits can move and bend up to 500 million times without failure. The excellent thermal stability of polyimide also enables the circuit to withstand extremely high temperature applications. The thermal stability of polyimide provides a better basis for surface mounting than hard boards. Because the flexible base film exerts less stress on the welded joint, thermal mismatch is unlikely to occur.

Repeatable wiring - Our circuits are made with exact copies of original drawings for excellent manufacturing consistency. Etched circuits replace welded and hand-wired connections for rigid plates, completely eliminating wiring errors.

Simplified circuit geometry - Flexible circuit technology places surface-mount electronics directly on the circuit, simplifying the overall design. Complex patterns that are almost impossible to achieve using rigid circuit boards can be easily achieved in flexible circuits.

Package size and weight reduction - Multiple systems in rigid plates increase weight and utilize more space. The flexible circuit contains the thinnest dielectric substrate. The thinness allows for a more streamlined design without the need for heavy rigid plates. Elasticity and flexibility reduce package size. In addition to reducing package size, reducing package weight is another benefit. With the growing demands of the electronics industry, weight reduction keeps flexible circuits extremely competitive.

In short, if you have flexible circuit design or flexible printed circuit board needs, we can help.

304 stainless steel

Conductor - Copper is the most widely used conductor and comes in a variety of thicknesses to meet each customer's requirements. Conductor options include:

· Rolled Copper (RA)

· Electrolytic copper (ED)

· Aluminum

· Carbon

· Silver paste

· Stainless Steel ®

· Constantan

Double sided flexographic laminated adhesive

Adhesives - The choice of adhesives depends on customer requirements and conductor thickness. Common adhesives include:

· Epoxy resin

· Acrylic fiber

· Pressure Sensitive Adhesive (PSA)

· No adhesive (substrate)

Dual layer flexible circuit board with flexible solder shield

Insulators - Flexible substrates (substrates) and cladding materials are available in a variety of thicknesses and are supplied by several manufacturers. Common insulators include:

· Polyimide

· Polyester, polyethylene naphthalate (PEN) and polyethylene terephthalate (PET)

· Solder resistance layer

· Flexible solder resistance layer

· Imageable Covering Film (PIC)

· Screen printing dielectric

3 layers flexible.5 oz copper selective lead bonding Ni/Au assembly and radiator bonding

Surface treatment - The final surface treatment depends on each customer's assembly requirements and the application of the finished product. Common surface treatments include:

· Solder (tin, lead or RoHS compliant)

· Tin

· Nickel/gold sinking

· Hard nickel/gold

· Lead key alloy

Organic: entek or organic solderability Protectant (OSP)

· Silver

· Carbon

In short, if you have flexible circuit design or flexible printed circuit board needs, we can help.